The Ministry of Industry (Kemenperin) continues to spur the improvement of the competitiveness of the national textile and textile product (TPT) industry, one of which is by trying to reduce dependence on imported textile raw materials.

The steps taken include encouraging the development of textile raw materials based on synthetic fibers.

"Synthetic fiber-based textile raw materials have many advantages, including high durability and can be engineered by imparting special properties and functions that support the performance of textile products. This property can be said to be eternal because it is implanted directly in the synthetic fiber raw material, "said Plt. Head of the Center for Textile (BBT) of the Ministry of Industry Wibowo Dwi Hartoto.

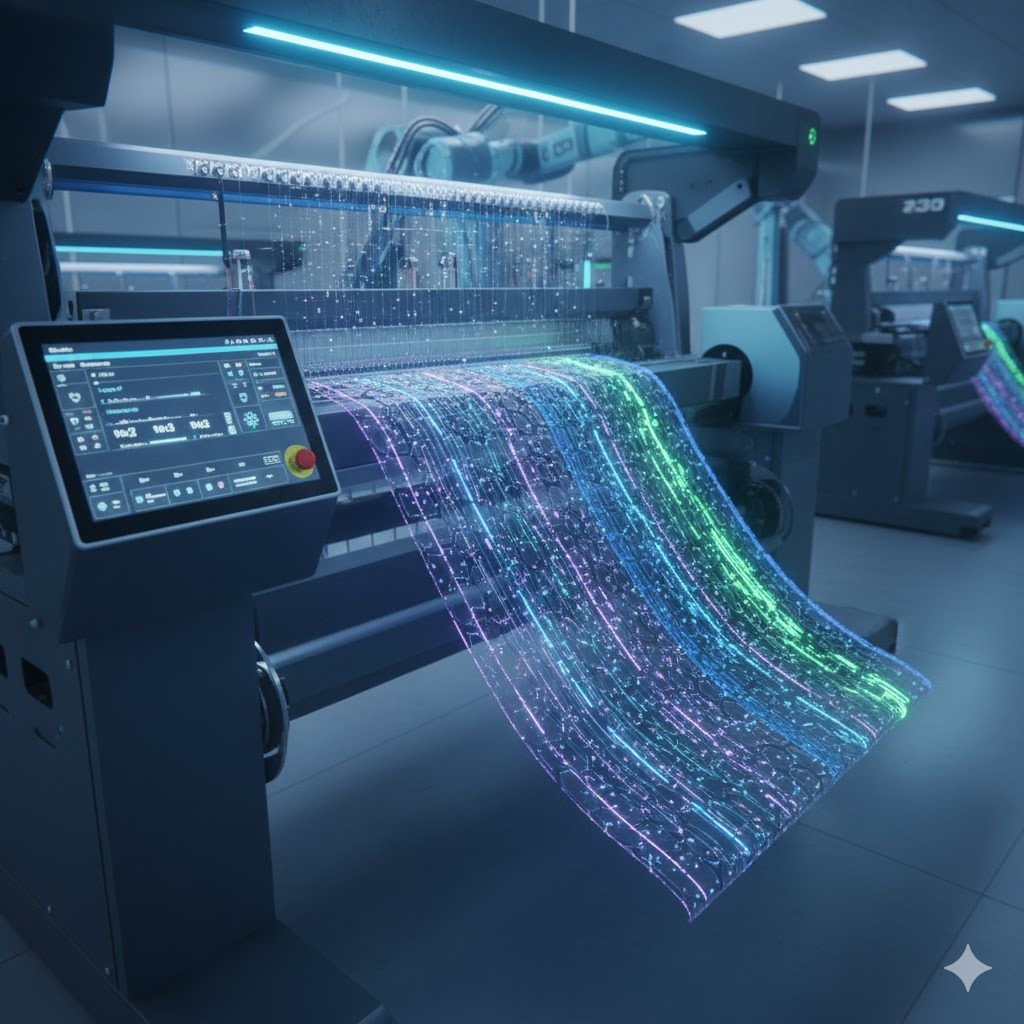

He said, as an effort to assist the textile industry players in developing synthetic fiber-based textile materials, the Ministry of Industry's BBT provides facilities in the form of an economical testbed. The facility is expected to be able to develop functional textile products. The textile industry players in the country are expected to be able to take advantage of this facility.

“The functional textile development testbed facility is equipped with laboratory-scale melt spinning facilities with the latest technology. The facility has the capability to process various types of polymers into filament yarn, ”he explained.

Polymers in question include standard polymers, engineering polymers, high temperature polymers, corrosive, and aggressive polymers, and bio sustainable and biomedical polymers.

The testbed facility enables the industry to develop products economically, because it only requires a small amount of raw materials, ranging from 0.5 kg to 2 kg to experiment which will produce formulas for various variants of filament yarn, both for clothing or functional apparel and technical textiles.

In addition, the development of functional apparel products is supported through color matching capabilities and the embedding of special functions in fibers such as anti-bacterial, anti-fire, or yarn manufacturing that supports convenience factors such as temperature control (thermo-regulator), quick dry, anti-wrinkle, and so on.

"As for technical textiles, the potential for textile products as raw material for other sectors such as aviation, health (biomedical), automotive, agriculture, construction, and so on," he continued.

The Head of BBT of the Ministry of Industry is optimistic that the testbed facility for the development of functional textiles will also encourage efforts for the independence of national textile raw materials, because it is already supported by the textile industry ecosystem in the upstream sector.

According to him, there is already a chip polymerization industry in the country as a raw material for filament yarn to the filament fiber spinning industry using melt spinning technology.

Data from the Association of Indonesian Fiber and Filament Yarn Manufacturers (Apsyfi) noted that there are eight polyester chip polymerization companies, 12 polyester filament yarn producers, four nylon filament yarn producers, and four viscose yarn producers.

"One of the obstacles experienced by this sector is that product development activities are not yet optimal due to inadequate human resources and research and development laboratory facilities," he explained.

Wibowo added, in developing testbed facilities for functional textiles, the Ministry of Industry's BBT also collaborated with various parties, including associations, academics, industry players, technology companies, government and startups.

"These efforts are expected to increase excellence and competitiveness achieved through access to resources, such as markets, technology, capital and human resources," he said.