As an effort to minimize global emissions, businesses around the world are required to be committed to reducing the carbon footprint of their production activities. One of the highlights is the textile and fashion industry.

Based on a report from UNEP, the fast fashion industry is said to be one of the industries that contributes significantly to carbon emissions, namely around 8-10% of world carbon emissions or greater with emissions from the combined global aviation and shipping industry.

In response to this, the trend of sustainable fashion is growing and is considered to be a solution to this problem.

Various labels have made various ways to ensure responsible fashion, for example using minimizing fashion waste by utilizing remnants of clothing manufacturing, using natural coloring techniques to re-recycling used clothes to become trendy fashions.

Not only that, textile raw materials originating from sustainable forest management can be one of the solutions in supporting a reduced carbon footprint in the fashion industry, for example viscose or rayon fibers.

This was explained by the sustainable forest management certification institution, Program for the Endorsement of Forest Certification (PEFC).

Speaking at the Innovation Forum for Sustainable Apparel and Textiles Conference, PEFC International Board Member Eduardo Rojas Briales said that with current technological advances, wood-based fibers can be used to produce textile products that are recyclable, renewable and biodegradable, with a low carbon footprint. from regenerative sources.

"As long as it comes from sustainable raw materials, viscose (rayon), acetate, lyocell and other forest fibers have great potential to make the fashion industry more sustainable," said Eduardo.

In Indonesia, rayon fiber has been able to be produced domestically, one of which is through the Asia Pacific Rayon (APR) operation which was inaugurated by President Joko Widodo in February 2020.

The largest integrated rayon production facility in Asia is also a driving force for the development of industry 4.0 in Indonesia.

This rayon fiber factory with a capacity of more than 240,000 tonnes / year is located in the same production complex as the raw material supplier, APRIL Group in Pangkalan Kerinci, Riau Province.

This joint location guarantees the quality of the integrated operation, whereby APRIL's supply of industrial pulpwood goes directly to APR for rayon production.

Meanwhile, pulp produced for raw materials can be traced and legally certified by PEFC which proves that the management of rayon raw materials is carried out in a sustainable manner.

Not only that, with its nature that comes from renewable and biodegradable raw materials, it makes rayon fiber attractive as a raw material for clothing that supports the concept of sustainable.

"With a number of advantages such as sourced from Indonesia, its biodegradable nature, and originating from renewable raw materials, rayon fiber can be an alternative as well as the future of textile raw materials. We can achieve the dream of making Indonesia one of the strengths of the world's textiles and fashion, ”said the Director of APR, Basrie Kamba.

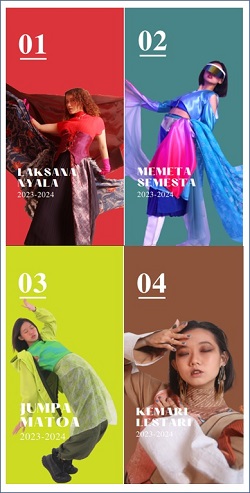

On the downstream side, APR initiated a collaboration platform to encourage the potential of the domestic children's fashion, textile and creative economy industries through the Jakarta Fashion Hub. This collaboration space allows fashion activists to innovate in producing fashion works that can support the development of the national textile sector.

In addition, APR also carries out various collaborations and partnerships, one of which is with Fashion for Global Climate Action from the UNFCCC, which is actively involved as a textile product producer company that supports sustainable fashion.

At the international level, APR is known to be the only textile company based in Southeast Asia, which signed the UN Fashion Charter for Climate Action, in August 2020.

Through this charter, more than 100 brands or institutions related to textiles and fashion commit to cutting greenhouse gas emissions from the supply chain by 30% by 2030, with a long-term target of achieving zero carbon emissions from the fashion industry by 2050.

Being more fashionable and in harmony with the preservation of nature is the key word for the future of the fashion industry.

It all starts with sustainably managed forests that play an important role in helping the world avoid the adverse effects of climate change, as well as supporting growth and development opportunities for economic growth in Southeast Asia.