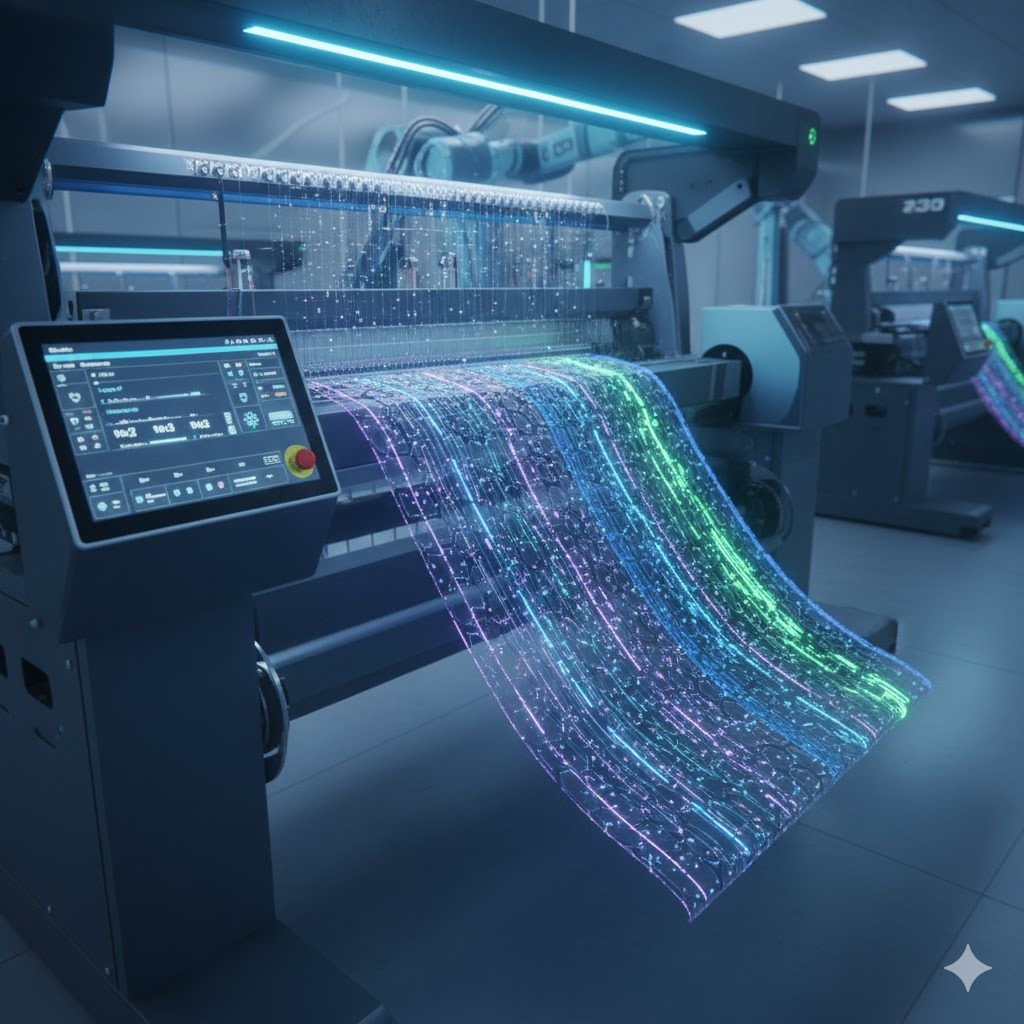

Electronically conductive fibers are already used in smart textiles, but in recent research articles ionic conductive fibers have been shown to be increasingly important. The so-called ionic fibers achieve greater flexibility and durability and correspond to the type of conduction our body uses. They could be used in the future for items such as textile batteries, textile displays, and textile muscles. An emerging research project in Advanced Materials Technology Implemented by doctoral student Claude Huniad at Borås University in Sweden, it is a track in a larger project, Weafing, whose goal is to develop an unprecedented new tactile stimulation garment that incorporates wearable flexibility. Actuator and sensor textiles.

The goal in the Claude Hunyadi project was to produce a conductive filament without any conductive metal.

“My research revolves around the production of electrically conductive textile fibres, and ultimately yarn, by coating non-metallic yarns sustainably on commercial yarns. The biggest challenge is the balance between preserving the properties of the fabric and adding conductive properties,” says Claude Honiad.

Currently, the uniqueness of his research lies in the strategies used when painting. This strategy extends to the processes and materials used.

ionic liquid

One of the pathways that Huniade is researching is a new type of material used as textile coatings – ionic liquids with commercial textile fibers. Like salt water, it conducts electricity, but without water. Ionic liquids are electrolytes that are more stable than saltwater where nothing evaporates.

“The maintainability aspect is an important requirement because textile manufactures can be harsh on textile fibers, especially if their use is extended. Fibers can also be woven or knitted without damaging them mechanically while maintaining conductivity. Surprisingly, the fibers are much finer in the process of being turned into fabric, rather than the commercial yarns they are made from,” explains Huniade.

Ionizing fibers can be used as sensors since ionic liquids are sensitive to their environment. For example, ionic fibers can sense changes in humidity, but they can also feel the stretch or pressure they are subjected to.

“Ionized fiber can really sparkle when combined with other materials or devices that require electrolytes. Ionizing fibers allow some phenomena that are currently confined in liquids to be possible in air in a lightweight manner. The applications are diverse and unique, for example for textile batteries, textile displays or muscle fibers. cloth".

Further research is needed to combine ions with other functional fibers to produce unique textile sets.

How do ionic fibers stand out compared to common electronic conductive fibers? “Compared to electronically conductive fibers, ionic fibers differ in the way they conduct electricity. They are less conductors of electricity, but they carry other properties that electronically conductive fibers often lack. Ionic fibers achieve greater flexibility and durability and suit our conduction types. used by the body." It's actually a better fit than electronic conductor fibers to how electricity is found in nature."