In order to support Indonesia towards the 4.0 Industrial revolution, a number of Taiwanese companies engaged in the textile manufacturing industry offer their superior products.

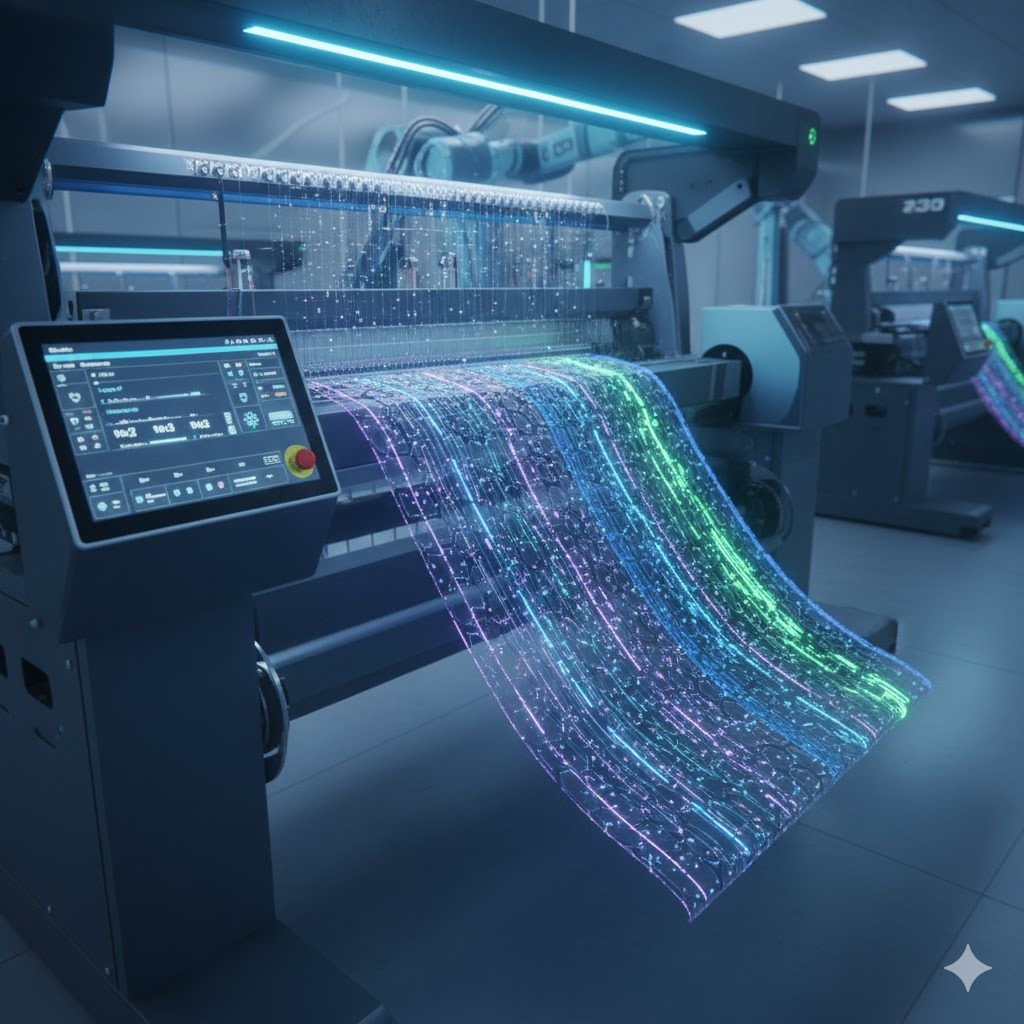

Taiwan's textile machinery industry is known to have an outstanding global reputation. With its emphasis on high quality and reliable service, the industry excels in providing flexible technology and textile integrated systems.

To show the latest developments in Taiwan's textile manufacturing industry to Indonesian companies, on Tuesday (30/3/2021), a webinar entitled "Taiwan Excellence Textile Manufacturing Solution" was held by the Bureau of Foreign Trade (BOFT) under the Ministry of Economic Affairs (MOEA) R.O.C. in cooperation with the Taiwan External Trade Development Council (TAITRA).

On this occasion, one of the Taiwanese textile manufacturing companies, Pailung Machinery Mill, which for several years has focused on smart knitting projects, has changed due to the wave of Industry 4.0. Pailung has launched MES (Manufacturing Execution System) and POMS (Pailung Online Monitoring System) to respond to a varied market and complex data management.

Their smart knitting machines provide services including optimizing adjustment time and machine accuracy, increasing the effectiveness of stock management and machine maintenance, accelerating the response from the manufacturing side to market needs, increasing product repeatability in production, effective data management in database knitting, and management and communication. effective remote control in the post-pandemic era.

"If we need to talk about the difference in advantages between Bankrupt and competitors, we have to define the 'Smart Knit'. Pailung not only provides monitioring in knitting but also provides control in the knitting process. It really can set the knitting procedure rather than just watching it, ”said Marketing Assistant Manager of Bankrupt Machinery Mill, Mason Chao.

He further explained that the reason his party chose Indonesia to market its products was because Indonesia was considered a big player in knitting, especially clothes and shoes. GDP from textiles in 2020 is more than 20% and CAGR (Compound Annual Growth Rate) of around 5%, indicating that the Indonesian market is very focused on textiles.

"We also have many references here. That is the reason we chose Indonesia as the basis for promoting POMS and MES. Apart from Indonesia, we also market our products to a number of other countries, including Vietnam, Turkey and India, ”said Mason Chao.