Advetorial

Inovasi Produk

Perspektif

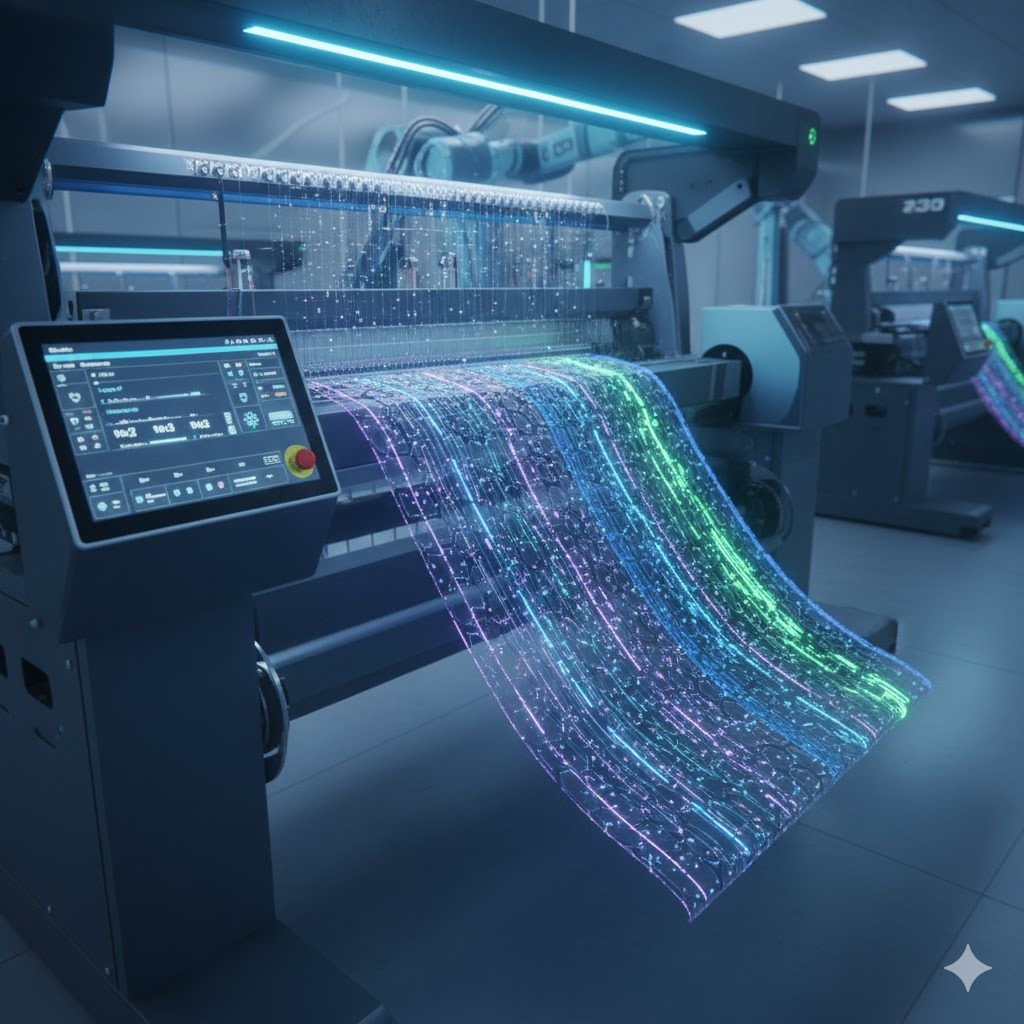

Teknologi

Berita Populer

- Industri Tekstil Tumbuh 7,43% di Kuartal III/2024 Meski Banyak Pabrik Tutup: Peran Restriksi Perdagangan

- Meski Diterpa Gempuran Produk Impor, Industri Tekstil Bandung Tetap Tumbuh

- Perpaduan Teknologi dan Tenun Tradisional: Sebuah Inovasi Terbaru

- Industri Tekstil Tumbuh Positif, Kemenperin Fokus Dorong Kemandirian Nasional

- Menuju Masa Depan Berkelanjutan: Inovasi Teknologi Tekstil Ramah Lingkungan