This sustainable fashion is a global movement that demands textile and clothing industry players to be more environmentally friendly in the midst of strengthening awareness of the need for sustainable products. In the last 15 years, the fashion world has indeed grown rapidly and massively in line with high demand and demand.

In the fierce competition in the world of fashion production, it is often not considered the aspect of sustainability so that its production has the potential to cause environmental impacts. Realizing this, fashion designers are now starting to commit to reducing waste by producing less waste or zero waste, including through the concept of sustainable fashion.

At the end of 2019, for example, the 2019 Fashion Trend which was held in Nusa Dua, Bali, started campaigning for environmentally friendly clothing. The argument is interesting, namely awareness of various kinds of pollution and environmentally unfriendly goods. Designers are starting to be inspired to create works of clothing that are more environmentally friendly by using materials that are easily recycled.

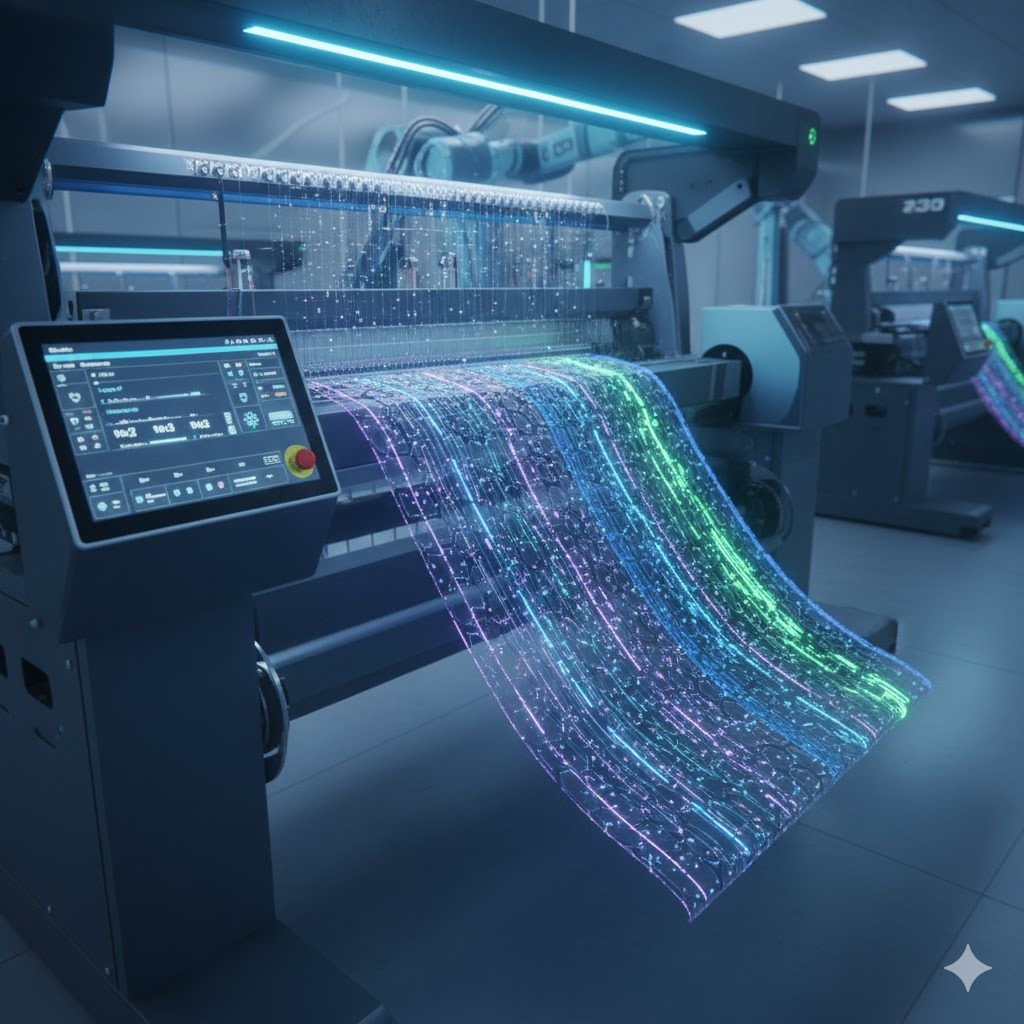

Environmentally friendly materials that are starting to be developed at this time include those made of rayon and wood called viscose. Currently, the largest viscose producer in Indonesia is Asia Pacific Rayon, located in Riau Province. The raw material is viscose rayon or yarn fibers that come from trees and can decompose naturally. In addition to clothing, viscose rayon can also be applied to various products, including household needs and health and beauty equipment.

Minister of Industry Agus Gumiwang Kartasasmita said optimizing the use of domestic textile raw materials is very important in boosting the performance of textile and textile products in Indonesia. Currently, the Ministry of Industry is taking several steps to continuously improve the performance of this labor-intensive industry. "To boost the competitiveness of the textile industry, we are pushing for many things. One of them is to facilitate the availability of raw materials in the country, "he said.

The Minister of Industry emphasized that strengthening the domestic industrial structure from upstream to downstream would increase national competitiveness. Thus, the products produced are of higher quality and can meet the needs of the domestic and international markets. "Optimizing the use of domestic raw materials is very important to boost the performance of the textile industry," said Agus.

One company that might be able to answer the government's challenge is PT Asia Pacific Rayon (APR). The company inaugurated its viscose rayon production facility in Riau last week. The facility, whose investment value reaches Rp. 15 trillion, is the only factory that produces textile raw materials in an integrated manner. Starting from tree nurseries where the wood is harvested as raw material for rayon to the production process.

Currently, APR's viscose rayon production capacity reaches 240,000 tons per year. APR targets the capacity to increase to 600,000 tons per year in the next few years. APR's raw material supply to the textile industry has been certified nationally (Verification System and Timber Legality) and internationally (Program for The Endorsement of Forest Certification).

Viscose rayon is a yarn fiber that comes from processed wood and can decompose naturally. APR's rayon fiber is classified as a sustainable material because it comes from renewable raw materials. The government hopes that these commodities can reduce textile dependence on imported raw materials. From the new facility, which accommodates around 1,500 workers, APR is projected to be able to generate foreign exchange up to USD 131 million (around Rp. 1.8 trillion). From there, the government hopes to get import substitution worth USD 149 million (around Rp. 2 trillion).

"So, in essence, the factory is a big leap for both export and import substitution," said Agus. The Ministry of Industry noted that the national rayon industry capacity currently reaches 857 thousand tons per year. This figure is up from 536 thousand tons per year in 2018. One of the reasons is the investment of APR and PT Rayon Utama Makmur through a rayon producing factory. In fact, the investment of the two companies has the potential to increase exports by up to USD 131 million (around Rp. 1.8 trillion) per year.

Director of the Textile, Leather and Footwear Industry of the Ministry of Industry, Elis Masitoh, added that the public's understanding that domestic brands are no less qualified than foreign brands need to be continuously improved. "We need to fight together for local industrial brands to be equal, so there needs to be an understanding in the community that brands from Indonesia are no less competitive. The government already has an action plan for the development of an integrated feces industry, starting from encouraging brand formation, improving product quality, promotion and marketing, expanding market access to increasing the skills and knowledge of human resources, "he said.